November 2014 Update

See short 10 minute video on Youtube

http://www.youtube.com/watch?v=T3uQs_lcKtY

Last update covered the covering process of the fuselage and tail assembly, here now is the next logical step: painting, final assembly of the fuselage and ready for taxiing.

Products for first two coats, hand rubbed with sponge to fill the weave. Top grade Latex exterior house paint. Yes, Latex exterior house paint. Did plenty of research, good UV protection. You put it on your house ? Right ? how long does it last ?

Third coat gets rolled on.

First layer gets worked in from below, ready

View from below, first coat

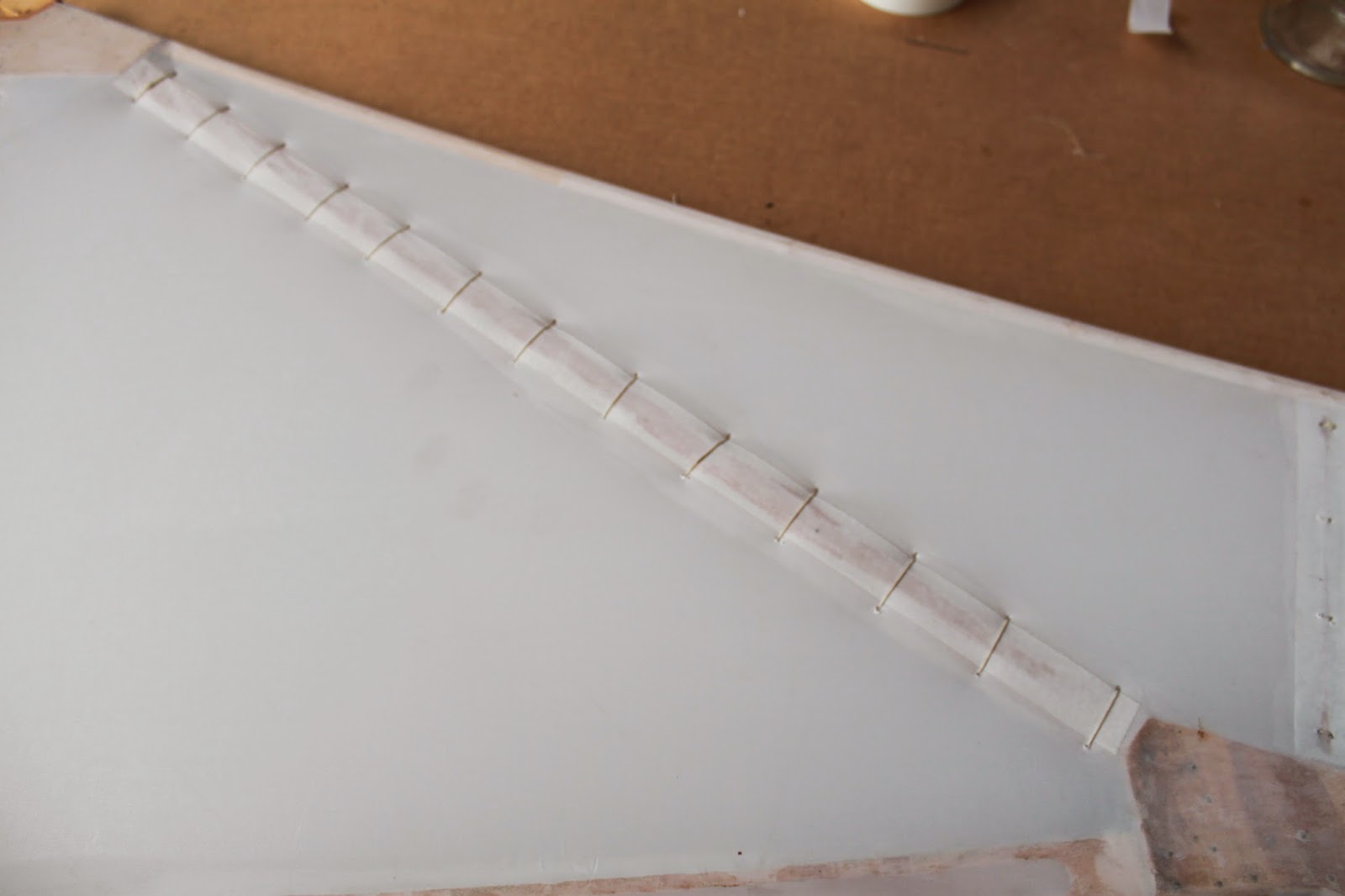

View from above shows where rubbed paint comes up through weave. Light areas are saturated with adhesive.

Translucent shows paint penetration.

After second sponge-rubbed coat.

Tail getting finished

Tail painted, third coat rolled on, turtle deck in place, elevator wires

Final wire installation and rigging. Outriggers now in place, finalized.

The Lohner emblem on the tail fin, after a bit of Photoshop clean-up

Green sides. Why green? Well, there are no color photographs and no text to indicate otherwise. Besides, Austria loved that color, it's used extensively by the military and the country is blessed with beautiful green pine forests.

Tail and rudders completed

New product, used by Boeing and Airlines to prep aluminum, no acids, works great. Costly, but easy to use, no environmental problems.

Panels prepped for painting

Side covers painted

Letters outlined

Masking

Removing Masking Tape

Finished

ASRA Painted

Side covers painted and lettered

Ready for wheels and axles

Installing wheels

Wheels are on

And we're off

And the tail is up.

Practice runs- see video http://www.youtube.com/watch?v=T3uQs_lcKtY

|

1912 |

B%26WVignette3.jpg) |

100+ Years Later, ready for taxi, 90% complete, just need wingsStay tuned. |

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)